Comprehensive Functional Safety: ISO 26262 Services for Automotive Excellence

In the automotive hardware and software development process, safety is not an option—it’s a fundamental requirement. Our Functional Safety services are rooted in the rigorous standards of ISO 26262, dedicated to ensuring that vehicles meet the critical safety performance levels necessary for the protection of passengers. From hazard analysis and risk assessment to safety validation, we provide comprehensive services to address the entire lifecycle of safety-critical systems in the automotive industry.

Concept Phase Solutions

Karnex’s Concept Phase Solutions are the base of our safety-centric design philosophy. In this phase, we lay the foundation for creating automotive systems that not only meet but also set new benchmarks in functional safety. This stage involves the meticulous planning and precise definition of product scope, ensuring every system is engineered with safety as the prime directive.

Item Definition

Karnex begins with a clear blueprint, defining the scope and purpose of automotive systems, aligning our designs with your safety expectations.

Hazard Analysis & Risk Assessment

We meticulously identify and evaluate potential risks, establishing a robust foundation for safety objectives.

Functional Safety Concept

Our strategic planning encapsulates rigorous safety principles to craft systems that prioritize user protection above all.

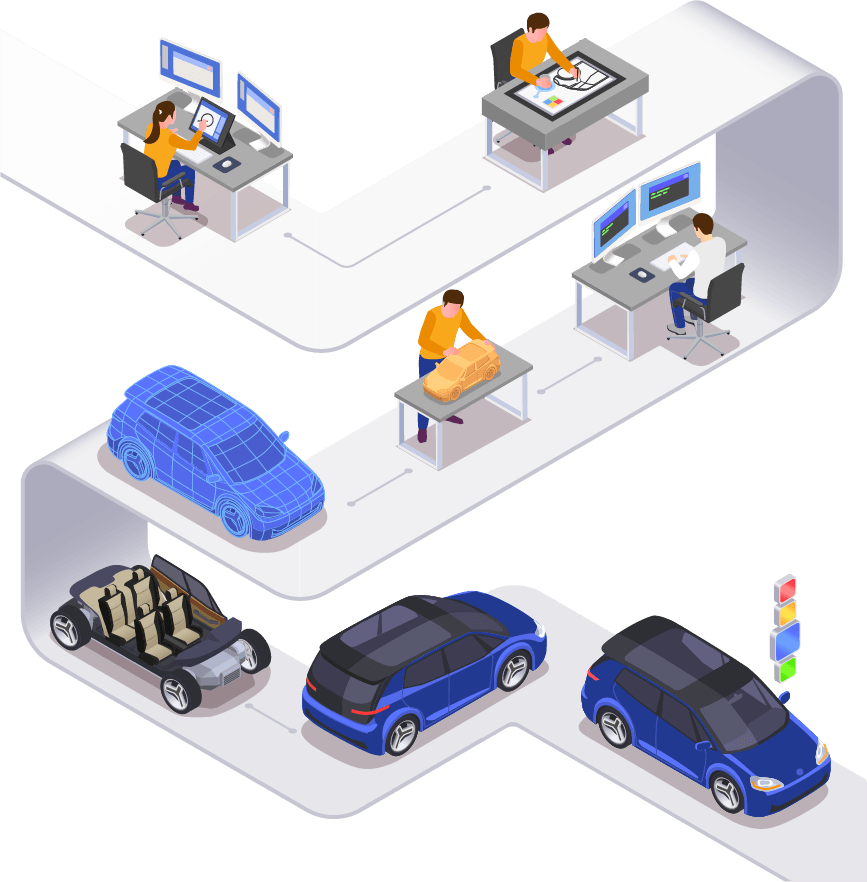

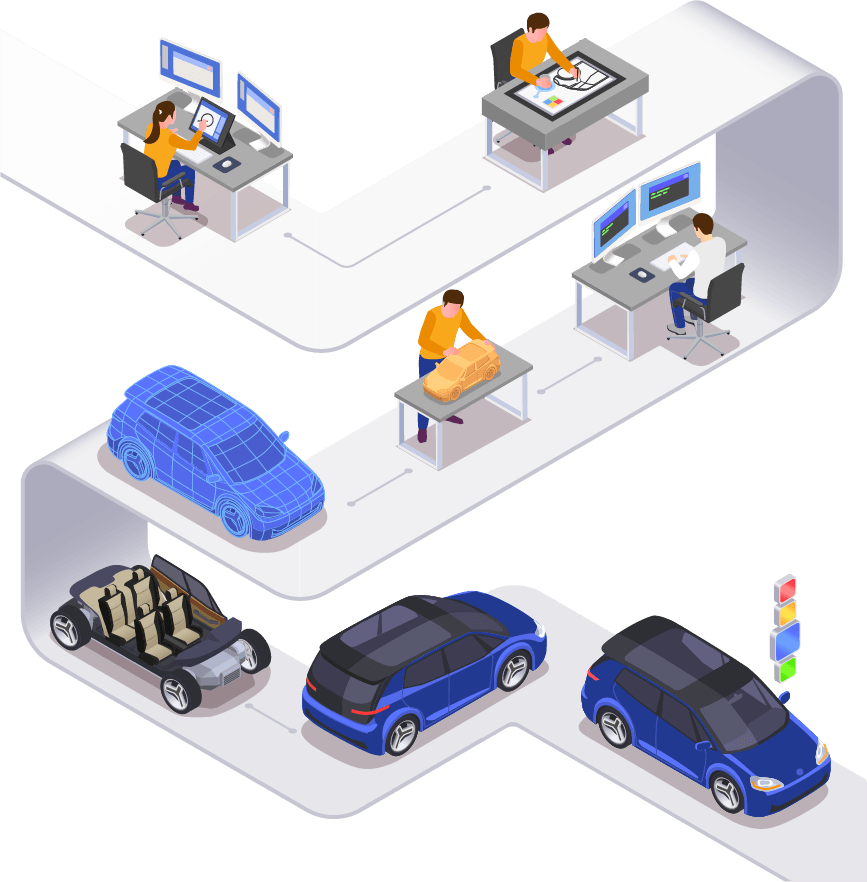

System-Level Development

Our System-Level Development transforms safety concepts into tangible systems. Here, we craft the architectural blueprints for safety, integrating technical specifications with rigorous safety standards. Our development process is a testament to our commitment to delivering systems that are both robust and reliable, underpinned by the stringent requirements of ISO 26262.

Technical Safety Concept

Karnex translates safety requirements into actionable technical strategies, ensuring each component contributes to overall system integrity.

System Architectural Design

We architect solutions that not only perform but persist, reinforcing the technical safety framework with resilient designs.

HW/SW Safety Assurance

Our dual focus on hardware and software safety assures that both elements of the system harmonize to create a secure automotive environment.

HW/SW Development

Hardware/Software Development at Karnex represents the convergence of precision engineering and innovative software design. We meticulously create hardware components and software algorithms that work in unison to uphold the highest standards of functional safety. Our development process ensures that every product is not just designed to perform but is also built to protect.

Precision Engineering

Detailed craftsmanship in hardware and software design sets Karnex apart, ensuring seamless performance and adherence to safety standards.

Safety Goal Evaluation

We constantly evaluate our engineering efforts against safety goals, ensuring no compromise on the safety front.

Integration & Verification

Our rigorous HW/SW integration and verification processes affirm that every unit operates reliably within the safety parameters.

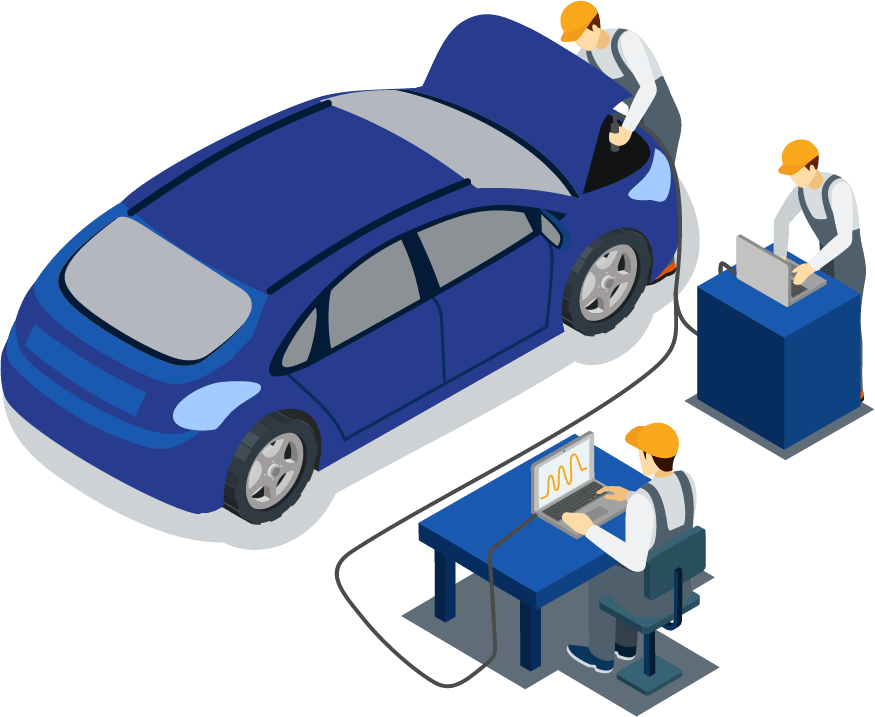

Production and Lifecycle Services

Production and Lifecycle Services at Karnex encompass the entire spectrum of a product’s life, from its inception to its retirement. Our approach ensures that every phase, including production, operation, service, and decommissioning, adheres to safety protocols. By considering the end-to-end lifecycle, we guarantee that our automotive products are safe, secure, and sustainable.

Lifecycle Planning

Karnex strategically plans for the entire lifecycle of our products, from safe production practices to responsible decommissioning.

Safety Validation

We validate the entire system against established safety goals, delivering confidence in the robustness of our automotive solutions.

Vehicle Integration & Testing

Through comprehensive testing protocols, Karnex ensures flawless integration of safety measures into the final vehicle design.

System Integration & Testing

Our integration services extend to the complete system, guaranteeing that the vehicle operates securely in any condition.

Dedicated HW-SW Interaction Testing

Karnex’s specialised testing for hardware-software interactions safeguards against system failures, guaranteeing a harmonious and secure operation.

Supporting Excellence

Our support services reflect our continuous efforts to enhance the reliability and safety of our automotive systems. This service ensures that every layer of product development is reinforced with specialised testing and validation, aligning with the highest standards of functional safety compliance.

Embedded Software Testing

Our embedded software undergoes rigorous testing, ensuring that it not only functions optimally but also aligns perfectly with safety mandates.

Ensure compliance with Functional Safety: ISO 26262 throughout automotive development via rigorous testing and comprehensive lifecycle services.

Our Blogs

Taming the Terrain: Overcoming Software Integration Challenges in Electric Vehicles

Introduction The electric vehicle (EV) revolution is in full swing, but Tier 1 suppliers face a unique set of hurdles on the road to a sustainable future. While their expertise in traditional automotive engineering is invaluable, navigating the complexities of EV software integration presents a new challenge. At KARNEX, a…

Attracting Top Talent and Cultivating Innovation: The Keys to Success in Automotive Software Development

Introduction The skillsets required to design, develop, and integrate software into complex vehicles have expanded dramatically. Today's automotive OEMs need a new breed of engineers with expertise in: The automotive industry is undergoing a seismic shift. Software is no longer just an afterthought; it's the very fabric of modern vehicles.…

Contact Us

Frequently Asked Questions

What are the services offered by Karnex under Functional Safety ISO26262 compliance?

Karnex will thoroughly analyse your hardware and software components by coordinating with your design and development team. Further, we will perform the following activities:

• Karnex uses HARA analysis to determine the ASIL levels during the concept phase of safety analysis.

• In-depth safety analysis at the system level

• Planning activities to ensure safety

• Safety analysis for hardware and software

• Will engage experienced and qualified functional safety consultants to review product and process

• We also perform functional safety analysis using your current stage of functional safety.

What value can the Karnex team add to deliver for ISO26262 FuSa consulting services?

Karnex has established a reputation among its customers and has been a preferred partner to various automotive OEMs for over a decade. With our strong domain expertise, we leverage exceptional consulting services for ISO26262 FuSa to deliver the following value-added services:

• To ensure the safety of critical functions and operational threads across the system, subsystem, and software levels, it is essential to thoroughly examine and validate their behaviour against established safety requirements within the functional safety framework.

• Exercising safety planning as part of the ISO26262-compliant safety lifecycle

• We evaluate and find critical checklists, tools, templates, and guidelines based on the project requirement.

• Towards a structured functional safety roadmap, we offer end-to-end technical consulting and support.

Will Karnex deliver functional safety training on-site and also support implementation?

The Karnex team can deliver on-site and off-site support for functional safety training and implementation. However, this depends on the project scope.

Will we get support from Karnex for only one phase of product development?

Karnex can support any project phase by understanding your requirements through coordination with your team.

We have an automotive product which is under development or ready for production. Whether Karnex can support us in ISO26262 at this stage?

Yes, Karnex will support for an under development automotive product or existing product by conducting a gap analysis at various levels of management including the process and technical levels. The need for gap analysis is to derive the safety gaps in the automotive product and to find the redressal measures to guarantee the compliance of functional safety.

What does Lifecycle Planning involve in ISO 26262 compliance?

Lifecycle Planning in ISO 26262 compliance involves strategic planning for the entire lifecycle of automotive products. This encompasses safe production practices, operational safety, service, and responsible decommissioning. The focus is on ensuring that every phase of the product’s life adheres to safety protocols, thereby guaranteeing that the automotive products remain safe, secure, and sustainable throughout their lifespan.

We have an automotive product which is under development or ready for production. Whether Karnex can support us in ISO26262 at this stage?

Yes, Karnex will support an underdeveloped or existing automotive product by conducting a gap analysis at various levels of management, including the process and technical levels. Gap analysis is crucial for identifying safety deficiencies in automotive products and devising remedial measures to ensure compliance with functional safety standards.

How is Embedded Software Testing conducted to align with safety mandates?

Embedded Software Testing, to align with safety mandates, is conducted through rigorous and thorough testing protocols. Karnex ensures that the embedded software in automotive systems functions optimally and complies with all safety standards and requirements. This involves extensive testing to identify and rectify any potential safety issues, ensuring the software performs reliably and safely under all operating conditions.

How does Karnex approach Item Definition in automotive systems?

Karnex approaches Item Definition in automotive systems by starting with a clear and precise blueprint that defines the scope and purpose of each system. This involves aligning the design with specific safety expectations and requirements. This meticulous planning ensures that every system is engineered with safety as a primary consideration, forming the foundation for all subsequent development phases.